Tel:+86-758-3138308 / 3138299

Fax:+86-758-3138300

Mr.Zhu Mobile:+86-13925930880

Mr.Hu Mobile:+86-13822673346

Web:http://m.tysms.cn

Email:fcsy@yataixcl.com

Address:No.11,YongSheng Rd.Nanjiang Industry Zone,Sihui,Guangdong

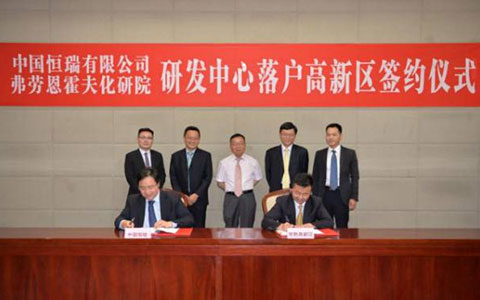

Germany's top science research institute to create an open platform to run the automotive lightweight for Henry China. In July 10th, China Hengrui Company Limited and Changshu national hi tech Industrial Development Zone signed the agreement, determined by the carbon fiber composite material industry leader Henry Chinese Limited (Hengrui Corporation) and eventually the German Fraunhof Association of top global scientific research institutions under the application of Chemical Technology Research Institute (Fraunhofer ICT) co founded the first Chinese, at the same time it is also Asia's largest in lightweight of automobile is the main research direction of advanced composite technology center (Advanced Composite Technology Center, hereinafter referred to as the ACTC R & D center, tentative) located in Changshu national hi tech Industrial Development zone. This center marks the establishment of the German Fraunhof Research Institute of Chemical Technology for the first time landing China, will direct the European mature carbon fiber composite materials research and development achievements, the introduction of technical personnel system to China, led the research and application of composite materials China towards new heights.

The total investment of the ACTC research and development center in the planning is 15 million euros, and the total area of R & D and office is over 8000m2. It is expected to be put into operation in 2018. After the completion, it will focus on the systematic research of automotive carbon fiber composite lightweight science and technology in the field. In the early stage, resin transfer molding, wet molding technology, thermosetting prepreg technology, thermoplastic unidirectional tape processing technology, injection molding and molding technology of thermoplastic and thermosetting composites were introduced. Through the process of development, new materials, technology and equipment, access to everything from product design, simulation analysis, tooling design, process design, mass production to automated production equipment, a number of high-end research and patents, and the first time the market, the auto companies to reduce the overall ecological cost. To enhance the core competitiveness of technology.

In the introduction of professional and technical personnel, the team of experts from Germany's top composite materials field will be resident center, and will set up long-term training projects, train a large number of China's automotive composite materials in the field of cutting-edge technology research and development personnel. At the same time, the selection of composite material industry outstanding in the global scope, professional materials and lightweight materials application in the field of talents to meet the needs of the future technology center, technology center and with the operation gradually mature, will gradually increase the proportion of local professional and technical personnel China.

After the completion of the R & D center, will comply with the domestic automotive industry development needs, take the "import digestion absorption innovation" development path, committed to serving the local enterprises in China, to build an open car lightweight research and development platform. The center will be experts in the field of lightweight, to help major automotive OEMs and parts suppliers systematically develop carbon fiber composite parts, while providing lightweight and mass production technology and solutions to meet the era of stringent energy conservation and emission reduction.

After the completion of the ACTC R & D center will provide carbon material sheet molding, wet molding, high pressure resin transfer molding process, compression resin transfer molding process, automatic tape laying, rapid prepreg, thermosetting resin injection molding process and other advanced technology. Technical team composed of professional top German composite technology development potential will according to the needs of domestic customers, product research and development work, and through the simulation and optimization of product performance prediction, and test to achieve the final product, will be seamless, laboratory technology and actual production, then, ACTC R & D center will play a bridge between experimental trial and industrial production, and gradually become a pillar of the lightweight technology of industrial grade application.

Fraunhof Institute of chemical technology has a wealth of practical experience in the integration of resources, in recent years, in-depth research and thorough analysis of the Chinese market. The future, Chinese Henry, Fraunhof Research Institute of chemical technology and R & D center ACTC customers through this platform, the development of cooperation mode and specific products, more efficient technology, business communication, so as to enlarge the industrial linkage effect, accelerate the localization process of the key technologies of new energy vehicles to.

It is imperative to reduce the weight of cars in the day

The energy saving and new energy vehicle industry development plan issued by the Chinese government stipulates that by 2020, the average fuel consumption of new cars will be reduced to 5 liters / 100 kilometers, and the energy consumption of energy-saving vehicles will be reduced to 4.5 liters / 100 kilometers. The major automotive manufacturers are aware that the key to the completion of this indicator is the lightweight of the car, the use of lighter parts and advanced materials in production, and is actively looking for solutions. At present, the global range of composite materials using only body weight less than 10%, to 2025, to reach 18% of the target to 20%, while the lightweight carbon fiber composite material into the China automobile market the biggest obstacle is that the rapid mass production techniques and the lack of professional skills and lack of knowledge. In addition, due to the lack of test and production equipment, domestic enterprises interested in mass production of carbon fiber products usually need to invest a large amount of money for research and development and testing, while the delivery of molds and materials to foreign countries will seriously delay the project development time.

In the international auto market, BMW, Porsche and other carbon fiber car market, driven and try to study the international automotive composite materials application. Fraunhof Institute of chemical technology began the research and development of composite materials and molding technology 10 years ago. In recent years, based on past experience, its research and development direction tends to product design, simulation technology development, the customer's real needs to maintain a high degree of attention, so that Fraunhof Institute of chemical technology is always at the forefront of composite materials application research. The Institute and BMW, Porsche has a number of successful lightweight components development project, and the formation of technology alliances, through alliances with other research units, build smart strategic network, each region based on thermosetting, thermoplastic materials, mixing three materials development path, to provide integrated solutions for customers.

Chinese Henry from Airbus supplier - Spain group (Carbures Group) Kappler exclusive introduction of the world's most advanced international patent composite products RMCP rapid production technology and equipment, the team gathered in the country's top master technology of composite materials, forming technology of engineering personnel, with most domestic an independent research and technology strength the ability to solve this year, won the first domestic car production project with the carbon fiber, and officially became the SAIC, GM, Changan, Geely and other well-known car suppliers, rising for the future market of carbon fiber composite products, the most powerful leader.

Favorable geographical conditions, regional industrial chain gradually mature

Changshu national hi tech Industrial Development Zone is located in the core area of the Yangtze River Delta, located in Chinese economic belt along the Yangtze River and the coastal economic belt gold interchange, by virtue of its traffic location platform richly endowed by nature and distinctive industrial clusters, complete and high quality and efficient management services, the rapid rise of economic strength and technological innovation ability, many times Jiangsu province was named one of the fastest development zone, won the three "the most investment value of Yangtze River Delta Development Zone", and was awarded the "national high technology service industry base in the core area", "national torch auto parts industry base" and "China cooperative innovation demonstration base" and so on.

In recent years, Changshu national high tech Zone adhere to the investment and Zhaocaiyinzhi two-way simultaneously, modern service industry and advanced manufacturing wheel drive strategy, the initiative to undertake advanced industries and high-end projects at home and abroad, the basic form of the automobile and parts, high-end equipment manufacturing, high-end electronic information and high technology service industry is the main characteristics of industry. In the park, the automotive and core components industry is accelerating. At present, the China automobile, TOYOTA automobile and other domestic and foreign more than 40 automobile and parts enterprises settled in the zone, formed a comprehensive R & D center as a leader, to the parts of the enterprise as the main body, the logistics park as a link in automobile and parts R & D, production, logistics and trade integration is complete the core of automobile and parts industry cluster. And the establishment of the ACTC R & D center will realize the government, enterprises, research institutions and colleges and universities multi linkage, intelligent manufacturing to build a composite industrial park in East China, to lead the overall upgrading of the existing automotive industry cluster.

People and development are unstoppable

When asked why he chose Henry as partners when landing Chinese, vice president of Fraunhof Research Institute of chemical technology, the direction of lightweight study leader Dr. Henning Frank for Henry affirmation and praise "Henry China shows between the lines open, inclusive and pragmatic style, sound development strategy and long-term, try new technology attitude. And Fraunhof can agree without prior without previous consultation Research Institute of chemical technology." Through several years of contact in operation, the two sides reached consensus on how to coordinate the existing technology marketization and meet the market demand in the field of composite materials. "This cooperation will be a win-win, we have a lot in common to enter the automotive lightweight China market, such as driving technology, drive, professional skills education, held by the needs of customers and open attitude, so ACTC will set up R & D center is an advanced and leading the cooperation".

Since Chinese Hengrui wholly owned subsidiary of Jiangsu Heng Rui Carbon Fiber Technology Co., Ltd. since 2015 settled in Changshu national high tech Zone, the preparatory work and daily operations have been Park support and cooperation. Located in the ACTC research and development center is a good practice of enterprise and government cooperation, has the sense of milepost type on both sides and the park, marking the combination of advanced composite materials, and automobile industry will enter the fast track, saving the cost of communication technology, improve the efficiency of technology transfer. The car companies and other customers can through technology center project cooperation to find solutions to break the bottleneck of technology and limitations.

To accelerate innovation, reduce the cost of product development, shorten the product development cycle, to promote close cooperation between Chinese and foreign R & D team with a deep understanding of ACTC, R & D center is Chinese and Henry Fraunhof of Germany Chemical Technology Research Institute jointly promote composite products to large-scale production, advanced and open platform to the customer terminal. As the leading R & D center of application and development of China's carbon fiber composite materials, the establishment of ACTC R & D center has broad reference significance for promoting the radiation effect of regional economy, industrial transformation and upgrading, and complementary advantages.